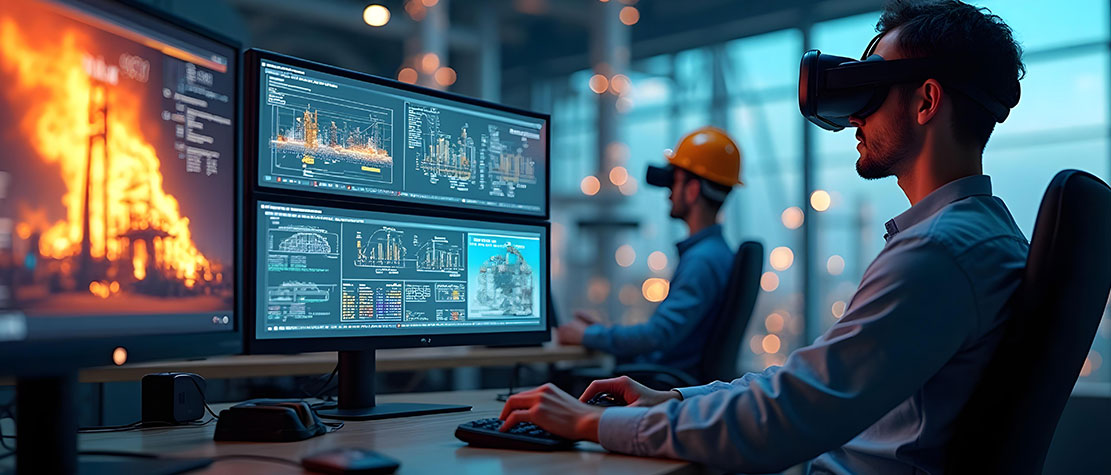

The oil and gas industry operates in some of the most dangerous environments worldwide, where fires pose a serious threat to worker safety, equipment, and business operations. In such high-risk settings, VR training for oil and gas has emerged as a game-changer. These immersive training experiences help workers not just follow rules, but act quickly during crises, turning emergency preparation into a skill that saves lives, protects assets, and safeguards the environment.

The High-Stakes Challenge of Fire Safety in the Oil & Gas Industry

The oil and gas industry faces special fire safety challenges because of its risky operations and involvement in dangerous materials. According to the National Fire Protection Association (NFPA), U.S. firefighters reported over 1.3 million fires in 2022, causing 3,800 deaths and $15.9 billion in property damage. Events like the Deepwater Horizon disaster in 2010 show the terrible results of poor fire safety measures, leading to deaths and serious environmental harm.

Limitations of Traditional Training Approaches

Fire safety training in oil and gas usually includes lectures, manuals, and occasional live drills. While these methods provide basic knowledge, they often fail to recreate the urgency, complex spaces, and overwhelming sensory input of real emergencies. VR-based training in the oil and gas industries offers solutions to these traditional approaches, which address several key problems:

- Safety Risks: Live-fire drills are practical, but are capable of endangering staff and harming the environment.

- Cost and Logistics: Large drills are expensive, time-consuming, and hard to organize, especially for offshore platforms or large refineries.

- Limited Repetition: Realistic drills rarely happen due to the cost and risk involved, thus limiting hands-on practice.

- Standardized Scenarios: Drills often follow expected patterns, missing many possible emergency situations.

- Knowledge Retention: Passive learning through presentations or videos leads to poorer memory than learning by doing.

The VR Advantage: Transforming Fire Safety through VR Training in the Oil and Gas Industry

VR safety training for the oil and gas industry poses several solutions to traditional training problems by putting trainees in simulated settings that look like real work environments. This technology creates a significant shift in fire safety education:

Key Benefits of VR-Based Fire Safety Training for the Oil and Gas Industry

- Enhanced Realism: AR/VR solutions in the oil and gas industry carefully recreate specific work environments, including complex machinery and control rooms, allowing for training that matches real situations.

- Risk-Free Learning: Trainees experience dangerous scenarios without actual danger, letting them make mistakes, understand results, and learn correct procedures safely.

- Realistic Scenario-Based Learning: VR training lets trainees respond to simulated fires in pipelines, compressor stations, or drilling platforms, all from a safe environment.

- Improved Knowledge Retention: Research shows that VR’s hands-on learning greatly improves information retention and helps trainees develop muscle memory for emergency responses.

- Safe, Repeatable Practice: Scenarios can be repeated as many times as needed without extra cost or risk.

- Customizable Scenarios: VR solutions can be tailored to specific facilities, roles, and emergencies that would be too dangerous to recreate in real life.

- Data-Driven Evaluation: VR systems collect performance data such as response times, action accuracy, and decision-making speed, which trainers can use for detailed feedback.

- Cost Efficiency: While requiring upfront investment, Virtual Reality reduces long-term costs of traditional drills, including equipment damage, fuel, and operational downtime.

A 2022 study by the National Institute for Occupational Safety and Health (NIOSH) found that workers trained with VR simulations responded 45% faster in emergency simulations compared to those trained using traditional methods.

Realistic Fire Scenarios Simulation Through VR

Interactive simulation for oil and gas can recreate various fire-related scenarios specifically relevant to oil and gas operations:

1. Refinery and Oil Rig Fires

Refineries and offshore oil rigs present some of the most dangerous fire risks due to their mix of flammable liquids and gases. VR simulation for oil and gas lets workers experience these high-risk locations where they learn to detect early gas leak signs and follow proper emergency response steps. These simulations recreate intense conditions, including limited escape routes and complex equipment layouts.

2. Warehouse Chemical Fire Simulations

Industrial facilities store hazardous substances that can catch fire. Through AR/VR in oil and gas training, employees learn about how chemical fires start, how to read Material Safety Data Sheets (MSDS) to identify fire suppression methods, and practice using foam and dry chemical extinguishers to prevent fire spread.

3. Electrical Fire Response Training

Building problems, such as faulty wiring, overloaded sockets, and equipment failures, can start electrical fires in processing facilities. The VR solution industry shows trainees how to recognize early signs like flickering lights and burning smells. These simulations teach how to disconnect power and use Class C fire extinguishers correctly and safely.

4. High-Rise Building Evacuations

Fires in multi-story facilities create especially dangerous situations due to their height and complex escape routes. VR training solutions create burning high-rise simulations requiring people to find exit stairwells, stay low to avoid smoke, and help others evacuate. Through these simulations, personnel learn how fires move upward and the importance of fireproof doors and stairwells.

Success Stories of VR Training within the Oil and Gas Industry

Leading companies are increasingly investing in Virtual reality training to improve fire preparedness. The Oil and Gas industry has been coming forward to incorporate safety training through VR to tackle the hazard posed by fire. Some companies that have started adopting VR are:

Saudi Aramco’s Digital Safety Initiatives

Saudi Aramco, known for using cutting-edge technologies, has seen real success implementing tech-based solutions for asset and safety management. In collaboration with Juego neXR, a notable RFID-based tracking system was developed to streamline the identification and movement of drilling assets under extreme field conditions. While that project primarily focused on asset integrity and operational efficiency, it reflects the organization’s broader commitment to digital innovation, making VR safety training for oil and gas a logical and forward-thinking extension of their evolving safety program.

Shell’s Immersive Training Labs

Shell has implemented VR training modules to train over 2,500 employees worldwide on emergency scenarios that follow international safety protocols. The company also uses VR to simulate fire emergencies on floating LNG platforms, training crews in changing wind and wave conditions.

BP’s Virtual Emergency Response

BP uses AR/VR in oil and gas to recreate offshore fire evacuations, improving muscle memory and readiness under stress. The company also uses multi-user VR environments where onshore and offshore teams work together in real time.

ExxonMobil’s Virtual Well Control

The company’s VR training solutions for oil and gas recreate blowout scenarios, reducing non-productive time during real incidents by 30%.

VR Implementation and Integration with Existing Systems

Technical Infrastructure Requirements

Setting up the VR training industry requires investment in hardware, software, and technical support. Organizations must decide whether to develop their own simulations or work with specialized training providers.

Integration with Existing Safety Systems

For best results, Virtual Reality should work alongside existing safety protocols and technologies. Organizations using advanced tracking systems for assets could include emergency response training that teaches awareness of these systems during evacuations.

Content Development and Customization

Creating realistic scenarios specific to company facilities requires significant expertise in both VR development and fire safety protocols. The most effective immersive training use simulations based on actual company facilities and equipment.

Measuring Training Effectiveness

Organizations need good methods to assess whether Virtual Reality training improves emergency response in real situations. This might include comparing incident response times and outcomes before and after implementation.

Synergy with Asset Management Systems

Effective fire safety isn’t just about training, it’s also about ensuring equipment reliability. Integrating AR/VR in oil and gas with asset management systems creates a complete safety ecosystem:

- Scenario Realism: Data from asset tracking systems can inform VR simulations. For example, a scenario might simulate a fire caused by a poorly maintained valve, showing the importance of asset tracking.

- Proactive Training: Knowing an asset’s tracked lifecycle allows VR modules to highlight risks associated with aging equipment.

Discover How VR Can Transform Your Safety Culture

Juego neXR's Solution: Creating the Next Generation of Fire Safety Training

Juego neXR offers a comprehensive VR-based fire safety training solution designed for the oil and gas industry’s unique challenges. Building on our successful track record with Saudi Aramco’s RFID-based tracking system for drilling equipment, our fire safety platform combines cutting-edge VR technology with deep industry expertise to deliver facility-specific digital twins, seamless integration with existing systems, customized scenario development, and comprehensive analytics. Our solution reduces incident response times by up to 45%, increases knowledge retention by over 75% compared to traditional methods, provides unlimited safe practice opportunities, decreases training costs by 35% over three years, and creates measurable improvements in safety culture through our proven implementation methodology of assessment, customization, integration, deployment, and continuous improvement.

Conclusion: A Safer Future Through Virtual Innovation

VR-based training represents a transformative approach to fire safety in the oil and gas industry, providing immersive, risk-free experiences that empower workers to develop the knowledge, skills, and instinctual responses necessary during emergencies while extending beyond individual preparedness to enhance the entire organizational safety culture through improved emergency response times, strengthened safety commitment, better regulatory compliance, and comprehensive risk mitigation. As the industry continues to embrace digitalization, organizations partnering with experienced providers like Juego neXR can leverage VR training solutions for oil and gas to create a safer, more prepared workforce ready to face the challenges of this high-risk environment, demonstrating their commitment to a culture of safety, resilience, and preparedness, essential qualities where there is little room for error.

Frequently Asked Questions (FAQs)

VR training solutions for oil and gas provide immersive, realistic experiences that simulate actual emergency scenarios without physical risk. Unlike traditional lectures and occasional drills, VR allows unlimited practice in facility-specific environments, improves knowledge retention by up to 75%, reduces response times by 45%, and provides detailed performance analytics that traditional methods cannot offer.

Implementing VR fire safety training requires VR headsets, compatible computers, specialized software, technical support, and potentially dedicated training spaces. Organizations can either develop proprietary simulations or partner with specialized providers like Juego neXR, which offer complete solutions including hardware, software, customization, and ongoing support tailored to specific facility needs.

VR fire safety training can be integrated with asset management systems by incorporating real-time equipment data into simulations, creating scenarios based on common equipment failures, teaching proper shutdown procedures for specific tracked assets, and emphasizing the connection between maintenance protocols and fire prevention. This integration creates a comprehensive safety ecosystem where training scenarios reflect actual facility conditions and equipment status.

Oil and gas companies implementing AR/VR solutions typically see ROI through reduced training costs (approximately 35% over three years), decreased incident response times (up to 45% improvement), lower accident rates, reduced downtime during emergencies, potentially lower insurance premiums, and increased regulatory compliance. The initial investment in hardware and software is offset by these benefits and the elimination of costs associated with traditional fire drills and physical training facilities.

VR fire safety simulations are highly customizable to specific facilities, with providers like Juego neXR creating digital twins that precisely replicate actual work environments, equipment layouts, and control systems. Training scenarios can be tailored to address facility-specific hazards, incorporate company-specific emergency protocols, simulate various emergency types (refinery fires, electrical fires, chemical spills), and reflect different environmental conditions (day/night, weather variables) that might affect emergency response in particular locations.

Revolutionize the future of business with Juego neXR

Table of Contents

- The High-Stakes Challenge of Fire Safety in the Oil & Gas Industry

- The VR Advantage: Transforming Fire Safety through VR Training in the Oil and Gas Industry

- Realistic Fire Scenarios Simulation Through VR

- Success Stories of VR Training within the Oil and Gas Industry

- VR Implementation and Integration with Existing Systems

- Juego neXR's Solution: Creating the Next Generation of Fire Safety Training

- Conclusion: A Safer Future Through Virtual Innovation

- Frequently Asked Questions (FAQs)

Related Posts

Share this Article:

Our Offices

India

Bangalore

GR Grand Plaza, 2nd Floor, JP Nagar, 6th Phase, Bangalore – 560 078

KSA

Jeddah

St Idris Square, 4036 Helmi Koutbi, Al Zahra, Jeddah 23425, Saudi Arabia

Follow Us On:

© 2026 Juego neXR. All Rights Reserved.